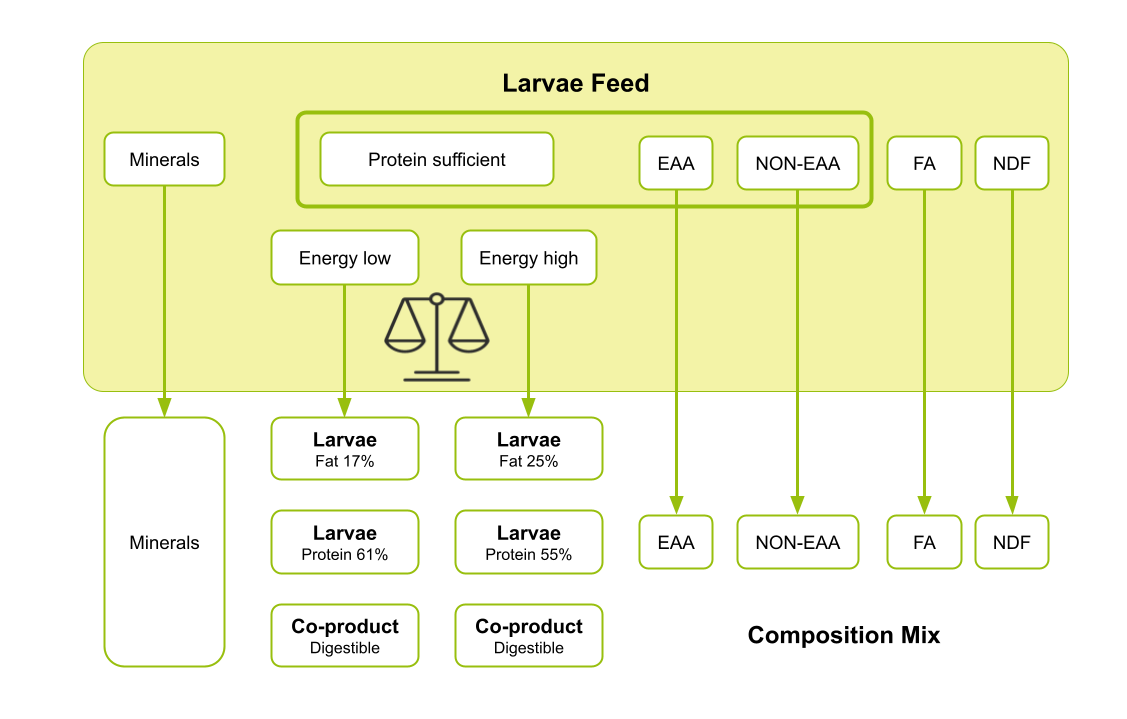

The Amusca Insect Breeding Module produces daily a mix of 5 tonnes of larvae, crude fibre and minerals. With the Amusca Insect Breeding Module we offer you the possibility to produce insect larvae in a safe and stable way. The system is scalable and cost-effective, allowing you to run it with relatively limited investment.

Depending on your desired production capacity, more modules can be installed at any time, reducing your investment risk and payback time.

Scalable

Whether on farm or large feed producing sites, the modular system makes it possible to adjust your required production capacity at any time, thus reducing your investment risk and the payback time.

Planet Friendly

Insects are quite efficient with the resources of our planet.

Produce on site with regional available raw materials

The insect larvae production is possible anywhere and at any time where sufficient co-products are available. From a sustainability perspective, Amusca promotes producing at the site where the larvae are needed.

Natural use of Antibacterial, Antiviral and Antifungi qualities of larvae

The production process is engineered to take advantage of the antibacterial qualities of the larvae during the larvae breeding process. Bacterial, viral and fungi related processes are immediately cut out during production. Bacteria, viruses and fungi at the end of the production process are expected to be well within the safety limits.

Economical benefits

With Amusca technology you an create a stable larvae production at a competitive price. Our technology converts substrates which are locally available into safe, high-quality larvae products with the aid of insects. By using our technology, you'll avoid all kind of intermediate steps, logistical costs and marketing expenditures. A perfect solution from an economical point of view.